Green Shaping Sand Making System: A highly efficient and intelligent solution for manufactured sand

Release Date:

2025-07-21

With the increasing scarcity of natural sand resources and stricter environmental policies, manufactured sand has become the preferred material for the construction, ready-mix concrete, and highway industries. Compared to natural sand, high-quality manufactured sand has the following advantages:

Green Shaping Sand Making System: A highly efficient and intelligent solution for manufactured sand

I. Application Advantages and Standard Requirements of Manufactured Sand

With the increasing scarcity of natural sand resources and stricter environmental protection policies, manufactured sand has become the preferred material for the construction, commercial concrete, and highway industries. Compared to natural sand, High-quality manufactured sand has the following advantages:

Controllable particle shape :Advanced crushing and shaping technology ensures that the particles are mostly cubic, with low needle and flake content, improving concrete strength and workability.

Stable gradation :The intelligent control system ensures that the finished sand conforms to GB/T 14684-2022《Construction Sand》 standards, meeting the gradation requirements of concrete with different strengths (C30-C80).

Environmentally friendly and energy-saving :Reduces the damage to the ecological environment caused by the mining of natural sand, and reduces carbon emissions through green production processes.

Standard requirements :Fineness modulus (FM) controlled at 2.3-3.0 ,Stone powder content (≤0.075mm) adjustable range 5-15% (According to concrete requirements). Crushing value ≤ 20% ,MB value (methylene blue value) ≤ 1.4 ,Ensuring low mud content and not affecting the durability of concrete.

II. Core Advantages of the Green Shaping Sand Making System

High-efficiency production, excellent particle shape. Sixth-generation sand making and shaping technology :Using Deep cavity impeller + high-frequency "stone-on-stone" crushing ,The finished sand particles are round and smooth, with a needle and flake content < 8% ,Crushing value lower than the industry standard. The system can simultaneously produce 1-6 types of aggregates of different specifications (such as 0-5mm, 5-10mm, etc.), meeting the diverse needs of commercial concrete, asphalt, and prefabricated components.

Intelligent control, energy saving and consumption reduction. Intelligent flexible production, through Aggregate flow metering + AI gradation control ,Adjusting crushing parameters in real time to ensure a finished product qualification rate > 98%。 Cloud control management platform Realizes remote monitoring, fault warning, and data analysis, reducing manual intervention by more than 50%.

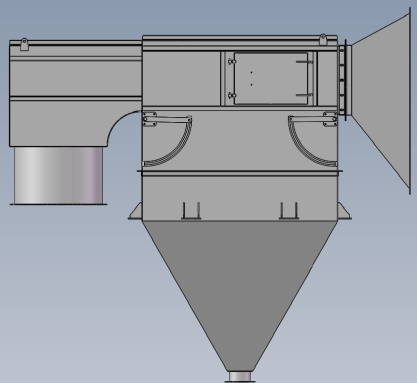

Precise powder selection, fine sand recovery. Using a fine sand recovery device to avoid the loss of fine sand above 0.075mm during the wind separation of powder sand, increasing the output of finished sand and ensuring economic benefits.

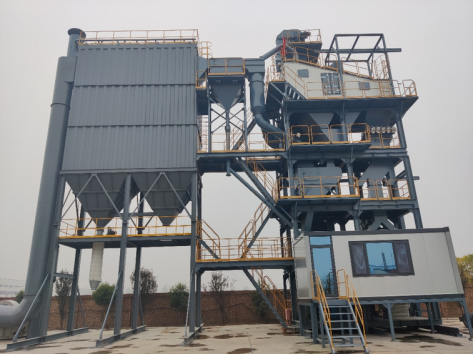

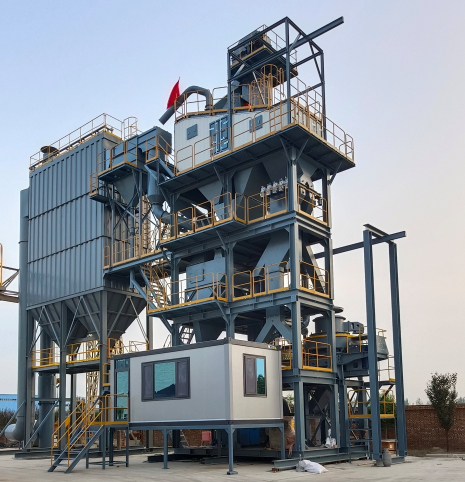

Modular design, flexible adaptation. The main building occupies only 400㎡ (20m×20m) ,Using Steel structure building ,Saving 30% space compared to traditional production lines, suitable for scenarios with limited space such as mines and construction waste recycling. Modular assembly to meet the needs of commercial concrete, highway engineering, etc. Mobile production needs 。

Green Shaping Sand Making System vs. Traditional Sand Making Scheme

| Comparison item |

Green Shaping Sand Making System |

Traditional sand making equipment |

|---|---|---|

| Crushing technology |

Deep cavity impeller + high-frequency "stone-on-stone", excellent particle shape (needle and flake <8%) |

Ordinary impact crusher, uneven particle shape (needle and flake 15%-25%) |

| Energy consumption |

2.7kWh/ton |

3.2-3.8kWh/ton |

| Intelligent control |

PLC+AI gradation control, cloud platform management |

Manual adjustment, relying on experience |

| Powder selection accuracy |

Stone powder content 3%-15% stepless adjustable |

Fixed wind selection, narrow adjustment range (8%-12%) |

| Space occupancy |

Modular building design (400㎡) |

Dispersed layout (600-800㎡) |

| Fine sand recovery |

Equipped with a high-efficiency fine sand recovery device to reduce loss |

No recovery or low efficiency (fine sand loss rate >10%) |

IV. Summary

The Green Shaping Sand Making System uses High efficiency and energy saving, intelligent control, and green environmental protection as the core, through Modular design, precise powder selection, fine sand recovery and other innovative technologies to provide customers with nationally compliant High-quality manufactured sand Compared to traditional equipment, it has significant advantages in particle size control, energy management, and intelligence and is an ideal choice for modern sand and aggregate production.